Continuous Inkjet

Videojet® 1280

Continuous Inkjet

Videojet® 1280

The easy CIJ printer to operate

Videojet has redefined simple with the Videojet 1280 Continuous Inkjet (CIJ) printer. From the intuitive interface to smart design features, it’s simple for all operators to use.

- 8″ tablet-inspired SIMPLICiTY™ interface

- Proven Videojet printhead and fluid systems

- One, easy-to-replace Videojet SmartCell™ service module

- All basic I/O ports included

Your goals are our goals

Focusing on 2 key elements, we are delighted to reveal our best value for money, general purpose continuous inkjet printer, designed with your needs in mind.

Ownership

made

easy

Class-leading reliability

The 1280 improves upon the proven Videojet printhead and fluid systems, providing stable performance and reliability across a broad range of operating conditions.

Improve start-up time

Don’t let variable volumes and production runs impact your start-up process.

Reduce costly waste

When you don’t have high utilization, ink supplies can expire before you get to use the whole cartridge.

When you don’t have high utilization, ink supplies can expire before you get to use the whole cartridge.

Videojet provides a wide selection of long shelf-life inks, with consistent print quality

across applications.

Videojet® 1280

if you need more information don’t hesitate to contact us

Remote access with VideojetConnect™ Remote Service*

CIJ printers with optional VideojetConnect Remote Service deliver on-board remote service capability.

* Subject to availability in your country

Help reduce unplanned

printer downtime

Temperature variations and dusty/humid plant environments can lead to unplanned printer downtime and/or poor printer performance.

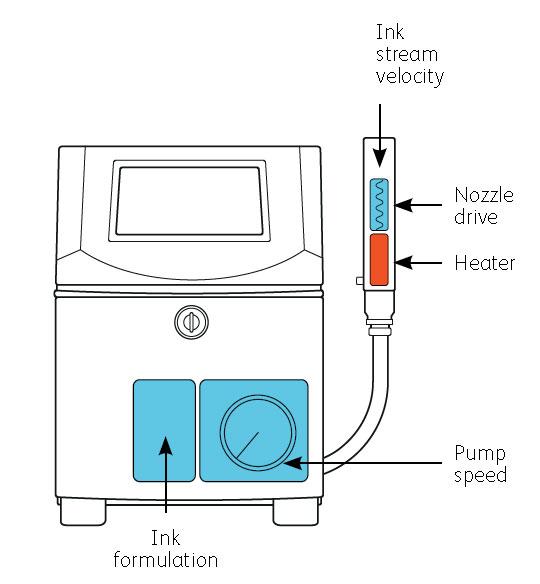

With Videojet Dynamic CalibrationTM

the 1280 constantly monitors environmental conditions and automatically adjusts jetting

parameters to help maintain superior print quality and maximize uptime.

Videojet® 1280

if you need more information don’t hesitate to contact us

Usability

made easy

Simple to use and maintain

Identify printer status, fluid levels, and what you are printing at a glance with our intuitive SIMPLICiTY™ touchscreen interface.

Easy to operate

You don’t need expertise to manage the day-to-day CIJ operations, be it code management or changing supplies.

SIMPLICiTY, our tablet-inspired 8” intuitive touchscreen interface, greatly reduces operator printer interactions to help eliminate potential user errors.

** Every year, or when the printer reaches 3,000 hours, whichever comes first.

Easy to maintain

Production capacity can be lost due to disruptive unplanned downtime or time-consuming maintenance.

Modular printhead design makes the most common replacements quick and simple.

The 1280 includes on-board, easy to understand ‘How to’ videos to guide you through basic tasks without extensive training.

Our no mess, no waste, no mistake Videojet Smart Cartridge™ system drains all fluids from the cartridge, and offers additional protection against leakage during transport and handling. Combined with the ease of service Videojet SmartCell™ design, there is no hazardous waste to worry about, helping to simplify routine maintenance.

Our no mess, no waste, no mistake Videojet Smart Cartridge™ system drains all fluids from the cartridge, and offers additional protection against leakage during transport and handling. Combined with the ease of service Videojet SmartCell™ design, there is no hazardous waste to worry about, helping to simplify routine maintenance.

Uptime Advantage

- Leveraging proven and innovative technologies from Videojet legacy models

- Modular wear parts enable easy and reliable replacement by the customer, therefore reducing downtime

- Ability to connect to optional VideojetConnect™ Remote Service for direct access to our technical experts

Code Assurance

- Tablet-like functionality enhances an operator’s ability to learn the interface to reduce coding errors

- The SIMPLICiTY user interface greatly reduces operator printer interactions, helping to eliminate potential user errors through an intuitive, 8″ touchscreen display

- User definable message rules can automate code content without need of operator interaction

Ink choices to match your application

Built-in Productivity

- No mess, no waste, no mistake Videojet Smart Cartridge™

- Reduce waste and rework with the step-by-step guides in the easy-to-use operator interface

- Automated message rules reduce operator interaction

Simple Usability

- 8″ touchscreen display is intuitive to the operator without the need for extensive training

- On-board ‘How to’ videos greatly reduce the need for having an operator manual to hand

- The SmartCell design allows for simple, user-performed preventative maintenance

Videojet® 1280

Continuous Inkjet

Line speed capability

Can print 1 to 5 lines of print at speeds of up to 533fpm (162mpm)

(10 characters per inch, single line of print)

Font matrix configuration

Single-line: 5X5, 5×7, 5X7 Tower, 7×9, 9×12, 10×16, 16×24, 25×34

Twin-line: 5×5, 5×7, 7×9, 9×12, 10×16

Tri-line: 5×5, 5×7, 7×9

Quad-line: 5×5, 5×7

Five-line: 5×5

Linear bar codes

UPC A&E; EAN 8 & 13; Code 128 A, B & C; UCC/EAN 128;

Code 39; Interleaved 2 of 5; GS1

QR codes

21×21, 25×25, 29×29, 33×33

Error correction mode L, M, Q or H

DataMatrix codes

Square Form up to 32×32; Rectangular Form up to 16×48

Nominal character height

Selectable from 0.079” (2mm) to 0.40” (10mm), depending on font

Throw distance

Optimal: 0.472” (12mm)

Range: 0.197” (5mm) to 0.591” (15mm)

User interface

8” high-response TFT-LCD touch screen

WYSIWYG touch to edit message editing

Custom logo/graphics

Can be created via optional CLARiSOFT™ software*

Character sets

Chinese, Russian/Bulgarian, Turkish/Scandinavian, Romanian, Greek, Arabic,

Japanese/Kanji, Faroese, Hebrew, Icelandic, Korean, East European, European/American and Vietnamese

Languages and interface options

English, Arabic, Bulgarian, Czech, Danish, Dutch, Finnish, French, German, Greek, Hebrew, Hungarian, Italian, Japanese, Korean, Norwegian, Polish, Portuguese, Russian, Simple Chinese, Spanish, Swedish, Thai, Traditional Chinese, Turkish and Vietnamese

Input/output

Product detect input

Encoder input

Beacon (Alarm light) output

Relay output

USB 2.0 (2x)

Ethernet LAN™

Message storage

More than 250 complex messages

Environmental protection

IP55 standard, no plant air required, stainless steel cabinet

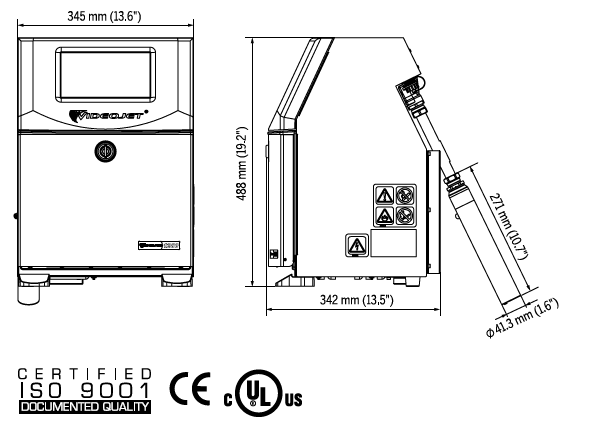

Printhead

Heated printhead

Diameter: 1.63” (41.3mm)

Length: 10.62” (269.8mm)

Printhead umbilical

Ultra flexible

Length: 6.56’ (2m)

Diameter: 0.91” (23mm)

Bend radius: 4.0” (101.6mm)

Fluids containers

Ink and Make-up Smart Cartridge™ 0.793 qt. (750ml)

Temperature/humidity range

32°F to 122°F (0°C to 50°C)

0% to 90% RH non-condensing

With selected inks; actual installation may require additional hardware

based on production environment conditions

Electrical requirements

Nominal supply power 100-240 VAC at 50/60 Hz, 80W

Approximate weight

Unpacked and dry: 39.5lbs (17.9kg)

Options

Dry air kit for high humidity and harsh environments (requires plant air)

Wide range of accessories

* CLARiSOFT Package Coding Design software required for bar codes and other advanced functionality.